Our Services

Comprehensive

Equipment

Maintenance

We offer a wide range of services for the technical maintenance and repair of metal recycling equipment. Our specialists have years of experience and use modern diagnostic and repair technologies to ensure the seamless operation of your equipment.

Our goal is not just to fix malfunctions but to prevent potential issues at an early stage. We provide comprehensive technical maintenance, including diagnostics of mechanical, hydraulic, and electrical systems, equipment load testing, replacement of worn components, and upgrading of control systems.

By using high-quality spare parts and a professional approach at every stage of maintenance, we extend the lifespan of equipment, reduce repair costs, and minimize downtime. We work with businesses of all sizes, offering customized solutions that meet their specific needs.

With our expertise and attention to detail, we guarantee the reliability, safety, and high efficiency of your equipment. Below are the key areas of our work.

Technical Inspection

Comprehensive Inspection of All Equipment Components

Regular technical inspection is the key to the uninterrupted and safe operation of equipment. Our specialists carefully examine all major components and assemblies, identifying even the smallest malfunctions at an early stage.

During the inspection, we analyze the condition of mechanical parts, assess the wear resistance of moving elements, and evaluate the overall technical state of the equipment. This approach helps to prevent unexpected breakdowns and reduces the cost of major repairs.

We use advanced diagnostic methods and precise measuring equipment, ensuring highly accurate inspection results. Thanks to regular technical inspections, your equipment will operate more reliably and have a longer service life.

Equipment Testing

Equipment Performance Testing Under Real Conditions

To ensure stable equipment operation, it must be tested under various operating conditions. We conduct full-scale testing of all systems under load, analyzing their performance in both standard and extreme conditions.

During testing, our specialists monitor the engine, mechanical components, hydraulic, and electrical systems. We evaluate their response to high loads and verify compliance with the specified performance parameters.

This approach helps to identify potential failures in advance and enhances equipment reliability. Regular testing extends the lifespan of machinery and reduces the risk of emergency production shutdowns.

Damage Detection

Diagnosis and Elimination of Mechanical Defects

Mechanical damage can lead to reduced productivity and even complete equipment shutdowns. We conduct a thorough inspection of all components for cracks, deformations, corrosion, and other signs of wear.

Our specialists use advanced non-destructive testing methods, such as ultrasonic diagnostics and laser measurements, allowing us to detect defects without dismantling the equipment.

Identifying mechanical damage at an early stage helps prevent severe failures and costly repairs. After diagnostics, we offer optimal solutions for restoring the functionality of the mechanisms.

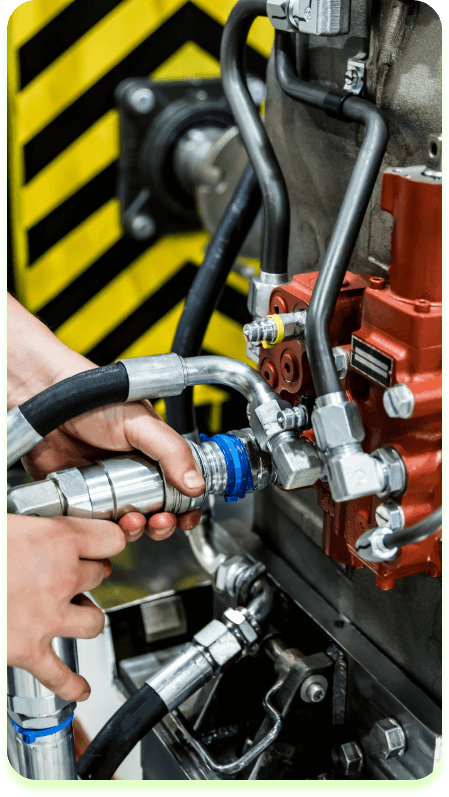

Hydraulic System Maintenance

Ensuring Smooth Operation of Hydraulic Systems

Hydraulic systems play a crucial role in equipment operation, and their condition directly affects productivity. We provide comprehensive maintenance for hydraulic systems, including oil and filter replacement, pressure checks, and seal integrity inspections.

Our specialists assess the condition of pumps, valves, and hydraulic cylinders, fixing any issues that may reduce equipment efficiency.

Regular hydraulic system maintenance extends equipment lifespan, lowers repair costs, and minimizes the risk of emergency breakdowns.

Comprehensive

Service and Maintenance Solutions

We provide a full range of services for the maintenance and repair of metal recycling equipment. Our specialists ensure the reliable operation of all systems, helping prevent breakdowns and reduce operating costs. With us, your business runs smoothly.